Table of Contents

Key Takeaways

Why Understanding Construction Hazards Is Crucial

7 Common Construction Safety Hazards and How to Avoid Them

- Falls from Heights

- Excavation and Trench Collapse

- Scaffolding or Ladder Failures

- Electrical Hazards

- Lack of Proper Personal Protective Equipment (PPE)

- Repetitive Motion Injuries

- Hearing Damage from Loud Noise Exposure

How to Choose the Right Construction Company for Safety

Frequently Asked Questions

Ensure Construction Safety with Claris Design•Build!

Key Takeaways✔ Falls from heights are a leading cause of construction injuries; use guardrails, harnesses, and safety nets to prevent falls. ✔ Excavation and trench work require shoring, sloping, and daily inspections to prevent dangerous collapses. ✔ Consistently enforce the use of personal protective equipment (PPE) like helmets, gloves, and eye protection to reduce injuries. ✔ Implement lockout/tagout procedures, GFCIs, and insulated tools to prevent electrical shocks and arc flashes. ✔ Rotate tasks, provide ergonomic tools, and encourage regular breaks to prevent repetitive motion injuries. ✔ Provide hearing protection such as earplugs and limit exposure to reduce the risk of hearing damage from loud noise. ✔ Conduct regular inspections and ensure scaffolding and ladders are properly assembled and maintained to avoid collapses. |

With the industry presenting a wide range of hazards, the importance of following strict safety measures cannot be overstated. In 2022, nearly 1 in 5 workplace fatalities occurred in the construction industry, with 38.4% of these deaths resulting from falls, slips, and trips. By understanding the most common hazards and taking proactive steps to mitigate them, companies can promote better construction safety, protect their workers, and ensure that every job site remains a safe environment.

Why Understanding Construction Hazards Is Crucial

Hazards on a construction site are inevitable, but accidents are not. Proper awareness and planning can prevent many injuries. By developing a comprehensive construction safety plan, employers can minimize the risk of accidents.

For instance, certain tasks like trenching or electrical work carry higher risks than others, and specific measures must be taken to mitigate those risks. Likewise, personal protective equipment (PPE) and fall protection systems are vital for ensuring workers are shielded from harm.

Key Benefits of Understanding Hazards

- Reduced Injuries and Fatalities: Awareness of potential hazards leads to better prevention strategies.

- Increased Productivity: Fewer accidents mean fewer delays in project timelines.

- Legal and Regulatory Compliance: Staying compliant with construction safety regulations helps companies avoid penalties and legal issues.

- Lower Costs: Fewer injuries mean lower medical costs and insurance premiums.

7 Common Construction Safety Hazards and How to Avoid Them

1. Falls from Heights

Falls are one of the leading causes of serious injuries and fatalities in construction. Workers are frequently required to work at elevated heights—on scaffolds, ladders, rooftops, or in unfinished structures—where the risk of falling is high. Even a fall from a seemingly minor height can result in severe injury or death.

How to Avoid It

To prevent falls, construction sites must implement fall protection systems. These systems include:

- Guardrails: Installing guardrails around edges where workers are at risk of falling.

- Personal Fall Arrest Systems (PFAS): Workers should wear harnesses that are properly anchored to prevent falls.

- Safety nets: In certain environments, safety nets can be placed to catch workers if they fall.

Another way to deal with this hazard is holding a Safety Stand-Down, a voluntary event where employers pause work to discuss safety, focusing on fall hazards and reinforcing fall prevention with employees. Supervisors should also frequently assess the work environment and ensure all fall protection equipment is properly maintained and functioning.

2. Excavation and Trench Collapse

Excavation and trench work are routine tasks in many construction projects, but they carry significant risks. A trench collapse can bury workers in seconds, trapping them under heavy soil or debris, often with fatal results.

How to Avoid It

A competent professional should inspect trenches daily to identify potential hazards like loose soil, water accumulation, or nearby vibrations from heavy machinery. Workers should also never enter an unprotected trench, as the risk of a collapse is too great.

The following safety measures should be in place:

- Shoring and Shielding: Installing protective systems like trench boxes or shoring to prevent soil from collapsing into the trench.

- Sloping: Sloping the trench walls away from the excavation site can help reduce the risk of collapse.

- Safe Entry and Exit: Ensuring there are safe, easily accessible entry and exit points, such as ladders, within the trench.

3. Scaffolding or Ladder Failures

Scaffolding and ladders are essential for many construction tasks, but they can also be a significant source of danger if not used correctly. Scaffolding that is improperly assembled or ladders that are unstable can lead to serious falls or structural collapses.

How to Avoid It:

The stability of scaffolding and ladders is crucial to preventing accidents. Construction safety measures for scaffolding and ladder use include:

- Proper Assembly: Scaffolding should be built on a solid foundation and installed according to manufacturer specifications.

- Guardrails: Scaffolds should have appropriate guardrails in place to protect workers from falling.

- Regular Inspections: Scaffolding and ladders should be inspected frequently for any signs of damage, wear, or structural issues.

For ladders, workers should:

- Ensure Stability: Always place ladders on even ground, and never use them on slippery or unstable surfaces.

- Use the Right Ladder for the Job: The ladder should be the appropriate height and weight rating for the task at hand.

4. Electrical Hazards

Electrical hazards are another significant concern on construction sites, particularly when working near power lines, live wires, or faulty equipment. Exposure to electrical currents can result in severe burns, electrical shocks, and even fatalities. Arc flashes—sudden releases of electrical energy—can also cause serious harm.

How to Avoid It

To ensure construction safety and reduce the risk of electrical accidents, workers should:

- Use Lockout/Tagout Procedures: Before beginning work on electrical systems, workers must ensure that all power sources are de-energized. Lockout/tagout devices should be used to prevent accidental re-energizing of equipment.

- Use Ground-Fault Circuit Interrupters (GFCIs): These devices protect workers from electrical shocks by interrupting the flow of electricity when a fault is detected.

- Wear Insulated Tools and PPE: Workers should use insulated gloves and tools when working near live wires or electrical systems.

Regular inspections of electrical equipment and wiring are also necessary to detect any potential issues early. Additionally, warning signs and barriers should be placed around high-voltage areas to prevent accidental exposure.

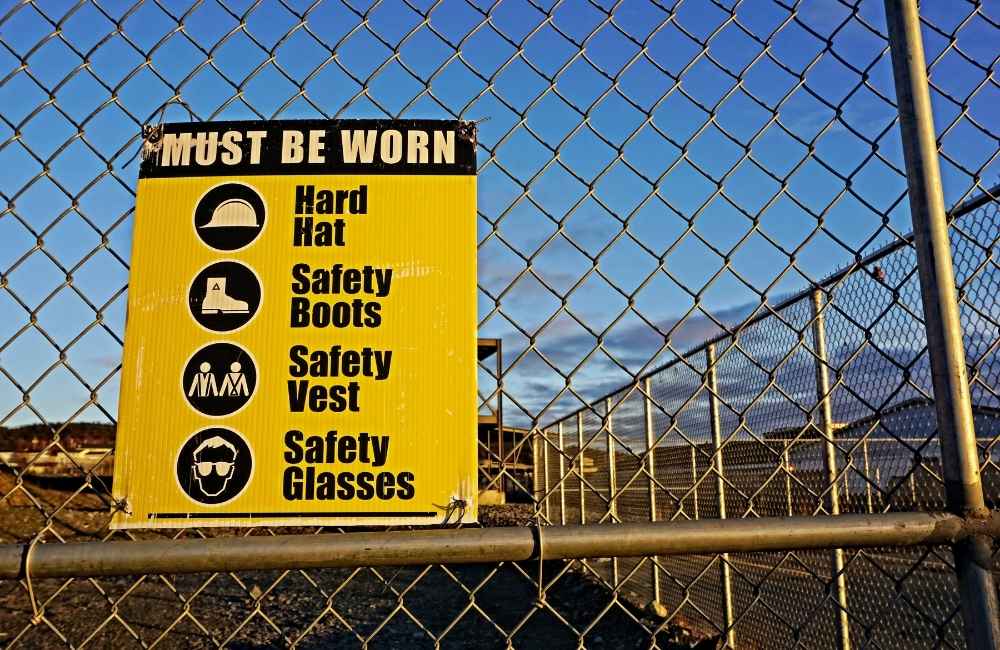

5. Lack of Proper Personal Protective Equipment (PPE)

PPE is the first line of defense against many construction hazards. However, when workers fail to wear the appropriate PPE—or when the equipment is inadequate—their risk of injury increases significantly.

How to Avoid It

Employers should enforce the consistent use of PPE on all job sites. The type of PPE required will vary depending on the specific hazards present but generally includes:

- Helmets: Protects workers from head injuries caused by falling objects or bumps.

- Gloves: Protects hands from cuts, abrasions, and contact with hazardous substances.

- Eye protection: Safety goggles or face shields protect against debris and chemical splashes.

- Steel-toed boots: Protects feet from crushing injuries.

- Hearing protection: Earplugs or earmuffs are essential for protecting against noise-induced hearing damage.

6. Repetitive Motion Injuries

Repetitive motion injuries are less severe than falls or electrical shocks, but they can have long-term consequences for construction workers. These injuries occur when workers perform the same physical tasks repeatedly—such as lifting, bending, or using tools—without taking breaks or changing their routines.

Over time, repetitive motions can lead to musculoskeletal disorders, such as tendonitis, carpal tunnel syndrome, or back pain.

How to Avoid It

Preventing repetitive motion injuries requires a focus on ergonomics and worker wellness. Construction safety measures to prevent these types of injuries include:

- Ergonomic Tools: Providing workers with tools that are designed to reduce strain on their bodies.

- Task Rotation: Workers should rotate between different tasks to avoid putting too much stress on the same muscle groups.

- Stretching and Breaks: Encourage workers to stretch before and during their shifts and to take regular breaks to rest their muscles.

- Proper Lifting Techniques: Workers should be trained in how to lift heavy objects without causing injury, including bending at the knees and using their legs to lift rather than their back.

7. Hearing Damage from Loud Noise Exposure

Loud noise is a common issue on construction sites, especially with the use of heavy machinery, power tools, and other equipment. Prolonged exposure to high noise levels can cause permanent hearing damage, and yet hearing protection is often overlooked.

How to Avoid It

To protect workers from noise-induced hearing loss, employers must take a proactive approach:

- Provide Hearing Protection: Earplugs or earmuffs should be provided to workers operating in noisy environments.

- Assess Noise Levels: Regularly monitor the decibel levels on the job site and implement controls to reduce noise exposure.

- Limit Exposure: Workers should spend limited time in high-noise areas whenever possible, and machinery should be maintained to reduce unnecessary noise.

How to Choose the Right Construction Company for Safety

A reputable company will prioritize safety, follow strict regulations, and implement effective strategies to prevent common workplace hazards. By choosing a company with a strong safety culture, you can ensure your project is completed safely, on time, and within budget.

Here are key factors to keep in mind when selecting a company:

- Verify Licenses and Certifications: Verify that the company has proper licenses and certifications. Some of the most common certifications include OSHA, Certified Safety Professional (CSP) certification, and First Aid/CPR certification. Ask for proof and check their standing with local authorities.

- Review Safety Protocols and Past Performance: Review the company's safety protocols and request their safety records. A strong safety track record shows they are committed to preventing accidents and delays. Companies that provide regular safety training to workers are preferable.

- Confirm Insurance and Liability Coverage: Confirm the company has comprehensive insurance, including liability and workers' compensation. This protects companies from financial responsibility in the event of accidents or damages on-site.

- Choose Experience and Specialization: Choose a company with relevant experience in projects like yours. Specialized companies often have deeper knowledge of safety requirements and hazards related to specific types of construction.

Frequently Asked Questions

What are the OSHA standards for construction safety?

OSHA standards for construction safety cover a wide range of hazards, including fall protection, scaffolding safety, trenching and excavation, and electrical safety. Employers must provide proper training and enforce the use of personal protective equipment (PPE). Compliance with OSHA regulations helps reduce accidents and promotes a safer work environment.

How often should construction sites be inspected for safety?

Construction sites should be inspected daily by a competent person to identify hazards and ensure safety measures are in place. Regular inspections help prevent accidents by catching potential issues early. Frequent safety checks are key to maintaining compliance and protecting workers from harm.

What training is required for construction workers to ensure safety?

Construction workers need training in the proper use of personal protective equipment (PPE), fall protection, and handling hazardous materials. OSHA also requires specific training for specialized tasks such as electrical work and operating heavy machinery. Ongoing training ensures workers stay up to date on safety protocols and reduces the risk of workplace injuries.

Ensure Construction Safety with Claris Design•Build!

For a construction project that prioritizes safety and quality, trust Claris Design•Build. Whether it’s commercial buildings, industrial facilities, or residential developments, Claris Design•Build has the expertise to handle a wide range of projects while maintaining the highest safety standards. With years of experience and a strong commitment to following safety standards, Claris Design•Build ensures every project is completed efficiently and without compromising worker safety.

Contact Claris Design•Build today to discuss your project and discover how they can help you maintain a safe, compliant worksite.

![[2025 UPDATE] Commercial Construction Cost per Square Foot in the US](https://www.clarisdesignbuild.com/wp-content/uploads/2025/04/2025-UPDATE-Commercial-Construction-Cost-per-Square-Foot-in-the-US-3.jpg)